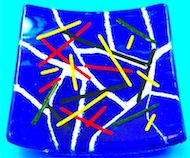

Art Glass Slumped

Dish

A kiln fused art glass slumped dish made from two pieces of fusing glass, frit and stringers.

The top glass is first cut into shapes and then fused to the base with glass frit filling gaps in the top surface.

Stringers are then contour fused to the glass before it is finally slumped in the glass fusing kiln.

A five inch square slumping mold was used for this project.

The size and mold shape can be changed if desired.

Fusing Materials:

One piece of of opaque fusing glass

One piece of clear or colored fusing glass

Fine white frit

Colorer stringers

Cutter

Slumping mold

Kiln wash or thinfire paper

Glass fusing kiln

Cutting & Assembly:

Step 1. Cut one five inch square piece of clear or colored glass, this will be the base.

Step 2. Cut the opaque class four and a half inches square. Then cut the piece in an abstract pattern.

The piece may also be broken by placing it between sheets of newspaper and gently tapping with a hammer.

Step 3. Place glass pieces on top of the base and move pieces out near the edge of the base glass.

Fill gaps with the fine white frit, mounding the frit up so that as it melts it will be level with the top surface.

Step 4. Place assembled item on prepared kiln shelf and put in glass kiln.

Fusing:

Use this fusing schedule to fuse glass.

The annealing stage has been removed as the dish will be annealed during the slumping process.

If fusing larger pieces then it may need to be adjusted.

1. 300°F up to 1100°F hold 20 minutes

2. 1300°F up to 1500°F hold 15 minutes

3. 630°F down to 94°F

When glass has cooled to room temperature remove from glass kiln.

Contour Fusing:

Cut pieces of colored glass stringers into various lengths and apply to plate.

Place item back into glass kiln and bring temperature slowly up to about 1400° F, the stringers are contour fused and not fully fused into the plate.

Switch kiln off and cool to room temperature before removing glass.

Slumping:

Apply four or five coats of kiln wash to glass slumping mold.

Make sure that any air holes in mold are not blocked with kiln wash.

Must be completely dry before use.

Sit fused glass plate in slumping mold and place in kiln.

Use the following slumping schedule, an annealing segment has been added for this stage of the process.

1. 300°F up to 1100°F hold 20 minutes

2. 100°F up to 1250°F hold 30 minutes

3. 9999 down to 960°F hold 60 minutes

4 150°F down to 750°F

5 Switch off, cool to room temperature

When glass has cooled to room temperature remove from kiln.

The kiln fused art glass plate should be nicely formed with the stringers clearly defined.

Return From Kiln Fused Art Glass Dish To Glass Fusing Projects

Return To Home Page