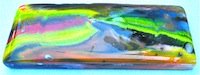

A Glass Pot Melt Produces

Colored Patterns

A glass pot melt occurs when art glass scraps are melted in a container at high temperature in a glass fusing kiln and the fusing glass flows in colored swirls from the bottom of the container.

Fusing glass pot melts, also known as aperture pours, produce a multi-colored swirl of colors that can be cut and used in other glass art fusing projects.

Scrap fusing glass is placed in a terra cotta, ceramic or stainless steel pot, which is then placed on kiln furniture in the glass fusing kiln, and melted, the glass flowing from the hole in the bottom of the pot.

Molds & Pots

Molds, terra cotta/ceramic saucers, stainless steel rings/squares or a kiln washed shelf can be used to catch the glass.

Fusing glass pot melt patterns can be varied by changing the hole shape in the pot or by having a number of holes in the bottom of the pot.

Extra holes can be drilled, or shapes altered with a drill, file or chisel. Pots with small holes in the side are also suitable.The height of the pot above the shelf or saucer will also influence the final pattern.

Multi-hole commercial ceramic pots in varying sizes are available individually or in kits.

If using terracotta pots try to obtain good quality pots as inferior pots may crack during the melting process.

Only compatible glass should be used for a pot melt, do not put different coe's in the same pot.

A variation of a pot melt is a screen melt where the glass is placed on top of a wire screen in the glass kiln and the glass drops through the screen to create an original pattern.

Stainless steel mesh is used for this process, it is not unusual for inferior mesh to shed black flakes during melting and for the flakes to be imbedded in the glasss.

Do not use galvanized mesh due to dangerous fumes.

For future reference, it is advisable to keep a note of the quantity and colors used for each melt.

When loading a pot dark colors should be kept to a minimum, they will overwhelm lighter colors unless used sparingly. A mix of white and other opaque colors will result in a nicely balanced color scheme.

It is probably advisable to only use three colors as too many colors may result in a muddy finish.

Preparation:

In larger kilns a number of pot melts can be set up without any problem.

When preparing the pot do not apply kiln wash, kiln wash needs to be heavily applied to the kiln shelf. Thin fire paper or fiber paper must not be used on the shelf as it may be picked up by the glass. Molds or saucers must be kiln washed.

If using stainless steel rings or squares sitting on a kiln shelf a strip of overlapping 1/8"fiber paper should be run around the inner rim. Use a straight edge to cut the strip as the bottom edge needs to be straight and even.

Pots are usually placed on ceramic strips, which are sitting on kiln posts or directly on top of a saucer or a ring.

When melting directly onto a kiln shelf ensure that the posts holding up the pot are well spaced to prevent them coming into contact with the glass.

Keep one shelf for use with melts as then can be very wearing on the shelf, whenever possible use some form of container to catch the glass.

To carry out a pot melt proceed as follows:

Step 1. Place glass pieces in selected pot.

Step 2. Using either prepared kiln shelf or container place in glass kiln and build framework to hold pot.

Step 3. Center pot on framework, check to ensure that posts will not come into contact with glass pour.

Step 4. There are many firing schedules for pot melts, the following schedule can be used for a three inch pot.

Melting:

During the melt you may need to adjust this schedule as pot size, glass weight and glass color as well as type of kiln may result in the need for an alteration to temperatures and firing times.

300 (150C) dph to 1000F (538C) hold 15 minutes

300 (150C) dph to 1100F (593C) hold 15 minutes

500 (260C) dph to 1650F (900C) hold 60 minutes

Drop AFAP to 1500F (815C) hold 45 minutes

9999 (as fast as kiln will go) to 950F (510C) hold 60 minutes(1 hour per 1/4” thickness)

100 (212C) to 850F (454C) hold 1 hour

100 (212C) to 650F (343C) hold 15 minutes then switch off.

Do not open until cooled to room temperature.

The finished melt may have a small section of stringer in the middle, this can be ground away if needed.

If the stringer is too thick then the glass may need to be fired again and the stringer melted into the glass.

The photo at the top of the page shows a glass pot melt that has been re-fired to fuse the stringer into the glass block.

Kiln wash may stick to the glass due to the high temperatures involved. Wet diamond hand pads are very good for removing any remainig kiln wash.

Finishing:

The glass pot melt can be cut on a tile saw to make fused glass jewelry, fused glass pendants, fused glass earrings or may be further worked to use as inserts for other glass fusing projects.

If it has been melted into a ring it can be turned into a lovely piece of glass art by cold working and fusing onto a glass base plate and capping with clear glass to make a stand alone ornament that can be mounted in a metal frame.

Round melts can also be enclosed with a contrasting color circular rim to produce an original piece of fused art glass.

Return From Glass Pot Melt To Glass Fusing Projects

Return To Home Page