Glass Contour Fusing

Glass contour fusing keeps the basic shape of glass pieces during the fusing process, it is very useful when making glass jewelry items in a glass fusing kiln.

The end result will be a softening of edges and nicely rounded corners without the pieces being fully fused together.

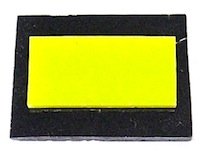

For this example two pieces of Bullseye COE 90 fusing glass are being

used, the black base is 1.75 inches x 1.25 inches. The top piece is

1.5inches x .75 inches.

Stack pieces together and place in glass fusing kiln.

Bring the temperature up to following contour fusing range.

The kiln temperature will be raised to between 1380 and 1440 degrees F which is the target temperature for this process.

It isn't necessary to use a formal firing schedule for small pieces like this.

After placing the shelf in the kiln, leave the kiln

lid slightly raised until the binders in the shelf paper have burnt

away.

Gradually raise the temperature to approx’ 1000 F and allow the binders to burn off and the shelf paper to return to its normal color.

The temperature is then raised to the target range with the lid closed.

Monitor progress, as it is easy to overshoot the temperature or leave the pieces too long at the target temperature.

This can result in the edges becoming distorted and beginning to shrink in the middle.

Once you are happy with the outcome turn the kiln off and let it cool to room temperature.

As can be seen from the photo the fired piece has retained its shape nicely and has soft and rounded edges.

The raised middle section can have a decal applied or can be painted with glass enamel or powder and re-fired.

You can contour fuse more than two pieces at a time, many jewelry

designs, particularly dichroic glass may have more than two layers.

Return To The Glassworks

Return To Home Page