Slumped Fusing

Glass Plate

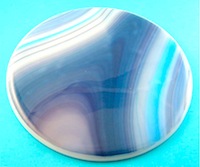

A fusing glass plate made from System 96 Nautica glass and one piece of System 96 white

The pieces are cut into circles, fully fused and then slumped into a plate mold.

A five inch diameter slumping mold is used for this plate.

This design style allows for different size slumping molds to be used.

Colors can be varied, transparent glasses will produce very striking results.

The use of paints and decals will result in very original

fused glass plates.

Fusing Supplies:

One piece of System 96 Opalart™ Nautica glass

One piece of System 96 white

Cutter

Glass circle cutter

Slumping mold

Kiln wash or thinfire paper

Glass fusing kiln

Fusing Instructions:

Step 1. Cut one circle from each piece of glass.

Step 2. Clean and dry pieces completely, place patterned circle on top of white circle and put on prepared kiln shelf.

Step 3. load shelf into fusing kiln.

Step 4. Use this schedule to fuse plate.

If fusing larger circles then it may need to be adjusted.

1. 330°F up to 1000°F hold 20 minutes

2. 1300°F up to 1480°F hold 15 minutes

3. 630°F down to 94°F

Step 5. When plate has cooled to room temperature remove from kiln.

Step 6. Apply kiln wash to slumping mold.

Must be completely dry before use.

Step 7. Sit fused circles in slumping mold and place in kiln.

Step 8. Use the following slumping schedule, an annealing segment has been added for this stage of the process.

1. 330°F up to 1000°F hold 20 minutes

2. 100°F up to 1200°F hold 10 minutes

3. 100°F up to 1250°F hold 25 minutes

4. 9999 down to 950°F hold 60 minutes

5 630°F down to 194°F

Step 9. When item has cooled to room temperature remove from kiln.

The plate should be nicely formed and clearly defined on the bottom as per photo.

Return From Fusing Glass Plate To Glass Fusing Projects

Return To Home Page