Make A Fused Glass

Powder Plate

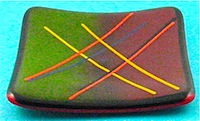

This fused plate has two pieces of fusing glass with a number of coats of sifted glass powder, tack fused between each coat.

When working with powder, particularly on a dark background, it is necessary to build the colors up in layers to prevent the base color showing through the powder.

In this plate red fusing glass is topped with a piece of black to which the powder is added, tack fused, stringers added, fully fused and then slumped in a glass slumping mold.

Colors and size can be altered to suit mold size.

It can also be made as a flat coaster, this type of design will produce some brilliantly colored pieces.

Fusing Supplies:

One piece of red and one piece of black glass 4" x 4".

Spring green and red glass powder.

Colored stringers.

Fusers glue.

One sifter.

Cutter.

Kiln wash or thinfire paper.

Face mask.

Slumping mold.

Glass fusing kiln.

Fusing Instructions:

Step 1. Cut red and black glass to size.

Wash and dry thoroughly and place black piece on top of the red glass.

Step 2. Place pieces on top of some paper before sifting powder.

Wearing protective face mask place green powder into sifter and gently tap sifter as it is moved across the surface to about half way.

Repeat with the red powder, it should slightly over lap the green powder.

Step 3. Lift item carefully onto prepared kiln shelf and place in glass kiln.

Bring temperature up reasonably quickly to about 1425° F, hold for about 15 minutes.

Turn off kiln and allow to cool to room temperature.

Step 4. Repeat Step 3, three or four more times until the black surface is nicely covered with the powder.

Step 5. Glue colored stringers across plate to form desired pattern.

When glue has dried put plate on prepared kiln shelf and place back into kiln to carry out a full fuse.

Fusing Schedule:

1. 300°F up to 1000°F hold 20 minutes

2. 350°F (331°C) up to 1150°F hold 5 minutes

3. 1300°F up to 1500°F hold 25 minutes

4. AFAP* down to 960°F hold 60 minutes

5. 600°F down to 200°F

6.Cool to room temperature.

(AFAP* as fast as possible)

Check during fusing process to ensure that plate doesn't overheat.

The plate should be fused as per the following photo.

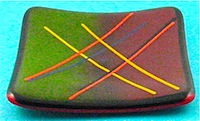

The next stage is to slump the plate, or it can be left as a coaster.

Slumping:

1. 330°F up to 1000°F hold 20 minutes

2. 100°F up to 1200°F hold 10 minutes

3. 704°F up to 1250°F hold 25 minutes

4. 9999 down to 950°F hold 60 minutes

5 630°F down to 194°F

Let plate cool to room temperature before removing from fusing glass kiln.

The plate should now be gently slumped as per the photo.

Using a lighter colored base along with contrasting powder and stringers will produce more striking results.

Return From Fused Glass Powder Plate To Glass Fusing Projects

Return To Home Page