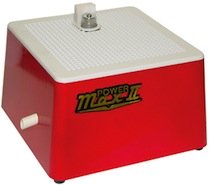

Glass Grinders

Tabletop glass grinders are one of the most useful tools for stained glass and fused glass artists.They are used to clean up rough edges and to shape and smooth items before or after cutting or fusing.

Although not absolutely necessary, a grinder reduces the time and effort required for some kiln worked or stained glass projects. Many projects would not be possible without a tabletop grinder.

Glass grinders are not overly expensive; there is a good range of models to choose from. Some models are less than $100; these may be more suited to someone who only wishes to carry out occasional projects.

Grinders come in a number of styles. They consist of a motorized vertical shaft with a removable abrasive head, called a bit.

Grinder Bits

The bits are diamond coated; usually two bits are supplied with a machine.

One bit is generally larger than the other allowing for large pieces of glass to be ground. The small bit is great for detail work and grinding areas the large bit can’t reach.

Using a water reservoir and a wet sponge behind the bit the glass is prevented from overheating or breaking. Importantly the wet system prevents ground glass from becoming airborne.

This is ground silica and can harm the lungs and cause lung disease.

You should always wear safety glasses when using a grinder. This is to safeguard against glass particles entering your eyes. Some people also wear a respirator whilst using a grinder.

Usually a 1” medium grit diamond coated bit will carry out most grinding and shaping operations. Bits are also available in fine and course grits and in different sizes and profiles for specialized grinding processes.

Using a special platform 1/4" and 1/8" bits can be used on a tabletop grinder.

Finishing

Grinding machines will not polish fused glass jewelry items. These items will need to be fire polished or polished with special equipment. Flat lap grinders or wet belt sanders are quite often used for final polishing.

Polishing compunds or special belts are sometimes used during final polishing operations. Normally a gentle glass kiln fire polish will be all that is needed for art glass jewelry.

The ground edges of glass should be scrubbed to remove grinding dust and dried before placing in the glass kiln for fire polishing or glass fusing. If the glass is not scrubbed properly it may result in a dark line around the edges of the glass.

If the glass is not to be fired immediately after grinding leave in a container of water until ready to clean and fire.

There are a number of accessories available for grinders such as special pliers to hold glass pieces whilst grinding, also tools to hold the glass against the bit to minimize the effort involved.

A large range of tabletop grinders and accessories can be found at Delphi Glass - Art Glass Tools & Supplies.

A grinder is a great piece of equipment; it makes light work of your clean up and shaping tasks.

There are other types of grinders such as a wet belt sander or flat lap grinders, which are more suited to larger items rather than glass jewelry pieces.

Return From Glass Grinders To Art Glass Tools

Return To Home Page